This was supposed to be an all new propulsion system for the RCX. It really does not use the RCX other then for a weight and for power. The program used make one thing: turn on two motors. That's it.

This project proved to be very poor performance. The drive system just spins on it's rubber belts and I was to lazy to rebuild it. I can't say I had a high sucess rate back then. But who gives a [strong word] anyway?

I might get back to this design and make it work some day, I like the idea. I saw somebody else did this some time after I did it though. But so? If my creations has to be unique I might as well quit. I build for the fun of it ,)

This wheel could move a little bit, not long but it could still move. Also I had to help it start by turning the wheel backwards so that the counterweight got up higher then the motor power could provide.

As you can see, I made the wheel pretty big. The main flaws are: It's not round. The counterweight is to close to the center and the belt drive has to little friction to make it work.

No, it didn't fall over, I placed it like this to take the picture ,)

Each wheel has six spokes connected to the medium pulley wheels in the center.

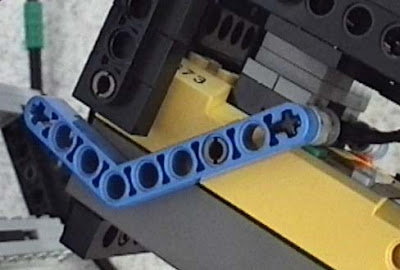

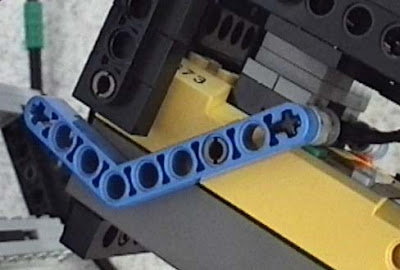

Since I hung the RCX under the construction I could not reach the buttons on it, hence these arms. Worked splendid for a change ,)

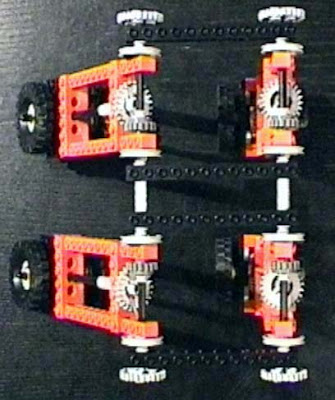

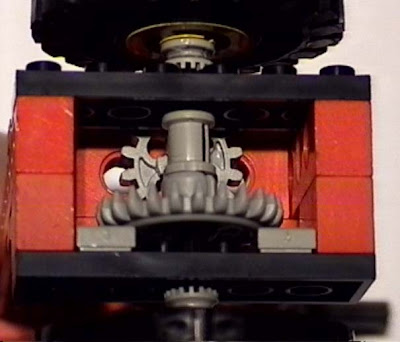

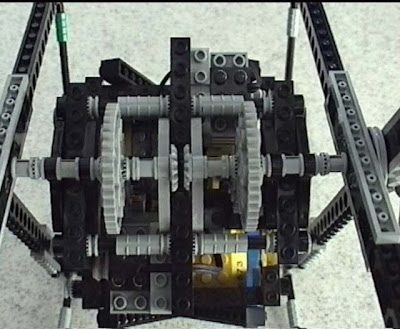

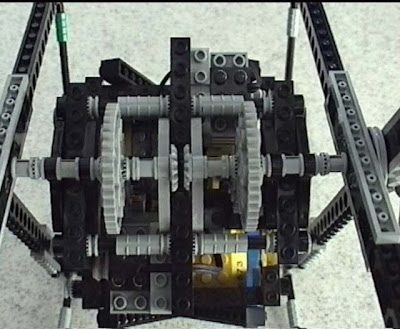

This is how the counterweight/propulsion system looks like. Like I said, two motors and belt drive.

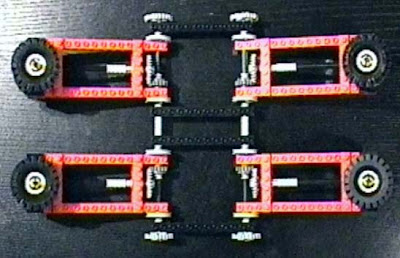

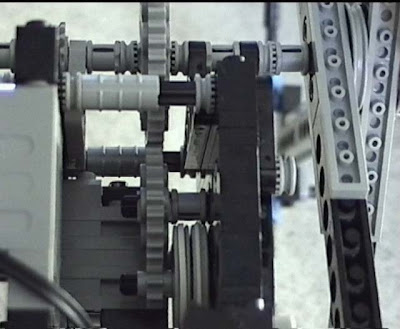

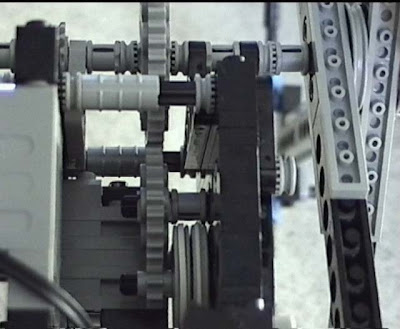

Here is a close up of one of the drive trains. You can also see the belt drive that I blame for this model not working.

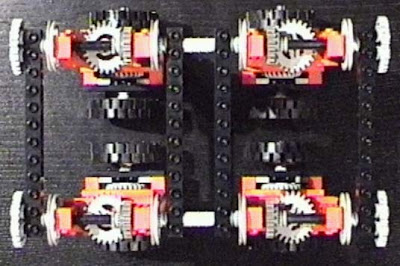

Top view of the weight. As you can see the drive axle is divided into two halves. I actually thought I could be able to drive the two different halves individually to provide it with steering. I was so naive :)

Another photo of the belt drive. I used but one belt first on each side and I had even more problems with the design. So when I was up for a toilet visit in the middle of the night it struck me I could use two belts on each side, so I redesigned it, also in the middle of the night. To no avail. I think it's because of this I tore the model apart. I had sooo much patience a year ago :)

Close up on the pulley/spoke set up and also the last picture.